GARDEN GROVE, Calif. – The Federal Highway Administration recommends using ultra high-performance concrete (UHPC) to build infrastructure that’ll last more than 75 years instead of several decades in stressful environments. A low water/cement-ratio portland cement mix reinforced with steel fiber, UHPC’s compressive strength can be four times greater than ordinary portland cement’s. In addition to providing extremely high strength, the concrete’s discontinuous pore structure significantly enhances durability by lowering permeability and increasing resistance to freeze/thaw damage and chloride penetration.

Many of these benefits are naturally inherent to Rapid Set® calcium sulfoaluminate (CSA) cement. For example, concrete made with our rapid-hardening alternative to portland cement reaches 4500 psi (31 MPa) in 1.5 hours compared to 28 days for portland cement concrete. Rapid Set®’s chemistry also better resists deterioration caused by chlorides, alkali-silica reaction (ASR), sulfates, shrinkage cracking and freeze-thaw cycles. It bonds extremely well to existing portland cement concrete. Because infrastructure built or repaired with Rapid Set® can be quickly reopened to traffic and requires much less long-term maintenance, most state DOTs use Rapid Set® cements, concretes, grouts and mortars.

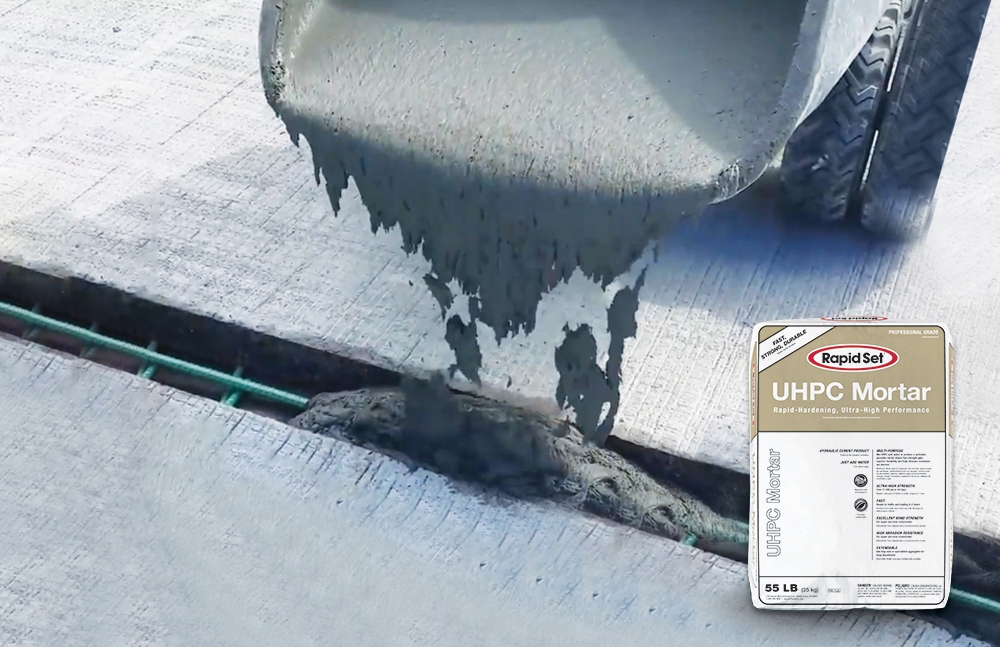

To help contractors and public agencies overcome particularly stubborn repair challenges in highly abusive environments, Rapid Set® UHPC Mortar is a pourable blend of Rapid Set®, high-performance additives and high-density aggregate that provides ultra-high strength without having to add steel fiber reinforcement or admixtures. Just add water to the powder in a standard mobile mortar mixer, place ¼-inch to 4 inches thick, and finish like a portland cement-based mortar.

Initial set time is 60 minutes. The mortar can be extended with trap rock or specialized aggregate for placements up to 2 feet deep without compromising strength. To satisfy specifications that require UHPC to contain steel fibers, simply add steel fiber. Strengths:

Use Rapid Set® UHPC Mortar to fill connections between precast pavement panels and structural bridge elements like girders to streamline construction and ensure long-term durability. Thin-bonded and regular pavement overlays and airport runways are also potential applications, as are industrial floors with extensive heavy traffic in a relatively small area, such as solid waste transfer stations and warehouse loading docks.

“We engineered this mortar to use the natural advantages of Rapid Set® cement to make a high-early-strength mix that allows public agencies to hit their strength targets and put projects back into service sooner,” says Vice President of Product Development Matt Sambol. “Besides its extremely high-early strength, Rapid Set® UHPC Mortar has low shrinkage, low permeability and excellent freeze-thaw resistance to provide long-term durability.”

Rapid Set® UHPC Mortar will be available in 60-pound bags and 3,000-pound bulk bags.

Questions? Contact Vice President of Marketing Janet Ong Zimmerman at 714-793-1010 or jong@ctscement.com.

About Us: CTS Cement Manufacturing Corp. manufactures Rapid Set® professional-grade calcium sulfoaluminate (CSA) cement products and Komponent® shrinkage-compensating portland cement additive used to make Type K cement for new construction and concrete repair and restoration. Contractors, owners, engineers, and architects choose our products to quickly deliver highly durable and aesthetically pleasing projects. Visit www.ctscement.com for more information – and connect with us to see how contractors use our products: